As the search for oil and gas moves farther offshore, it has become increasingly challenging to ensure reliable product flow. The crushing pressures and frigid temperatures of deepwater environments combine to increase viscosity and deposition, restricting flow and placing enormous demands on flowlines, risers and critical equipment.

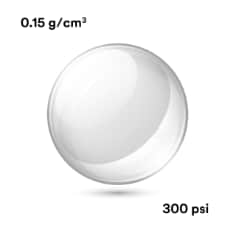

3M™ Glass Bubbles are high-strength, low-density hollow glass microspheres used in many kinds of syntactic foam compositions for thermal insulation and buoyancy. These foams can help improve equipment reliability in deepwater applications to help keep your product – and your profits – flowing.

3M glass bubbles are virtually insoluble in water, making them an excellent option for offshore applications. Their low thermal conductivity makes these density-reducing additives an excellent option for use in many wet pipeline and riser insulation applications. 3M glass bubbles are available in a wide range of pressure ratings and densities and are compatible with most resins. 3M glass bubbles can also be surface-treated to enhance bonding with the resin and minimize a foam's water pickup at high pressures.

Thermal Insulation

The need to operate at greater depths and with longer subsea tiebacks in turn requires strong, lightweight flowline and riser insulation with lower heat transfer. Compared to bulky, heavy pipe-in-pipe constructions, wet pipe insulation incorporating 3M glass bubbles are both easier and more economical to lay. Less than half the weight of pipe-in-pipe, these flexible flowlines offer a practical alternative that is easier to support in deep waters. Plus, the more compact construction means more pipe can be wound per spool, requiring fewer and smaller ships for installation.

Subsea flowlines

- Lighter weight, cost-effective alternative to pipe-in-pipe constructions

- Smaller pipeline diameter; more pipe wound per spool

Production risers

- Achieve OHTC (U values) of 2 W/m^2 K and below

- Steel Caternary Risers (SCRs), Top-Tensioned Risers (TTRs) and riser towers

Buoyancy

With an optimal balance of high strength and low density, 3M glass bubbles have become an industry-standard additive for syntactic foams used in buoyancy modules, buoys or buoyancy blocks for undersea vehicles. When 3M glass bubbles are formulated with resin, the resultant syntactic foam has a high strength-to-density ratio to provide maximum net buoyancy for a given depth rating.

Buoyancy modules for drill risers

- Help prevent the steel casing from collapsing under its own weight at depth

- Protect the drill string against ocean currents

Distributed Buoyancy Modules (DBMs)

- Maximum lift at the required ocean depth

Buoyancy blocks for Remote Operated Undersea Vehicles (ROVs)

- High net buoyancy foams rated to any ocean depth