Scotch-Brite™ Surface Conditioning Roll

- | Select product options for IDs.

Details

Highlights

- Available in a variety of sizes and grades to meet various project requirements

- Color coded by grade to reduce risk for error

- Works well on metal, plastics and composites

- Works well on metal, plastics and composites

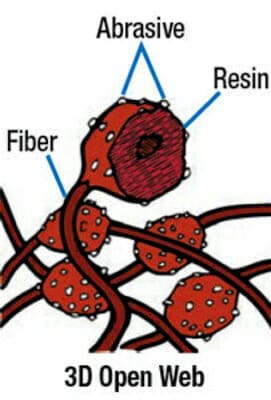

- Open web responds to surface irregularities while minimizing the geometry alteration on the part

Scotch-Brite™ Surface Conditioning Roll effectively blends, deburrs, finishes and cleans a variety of substrates. It can also be used for light grinding. The versatility of the Scotch-Brite™ Surface Conditioning Roll makes it a good all-purpose product.

Typical Properties

Resources

Similar products

Current product  Scotch-Brite™ Surface Conditioning Roll Scotch-Brite™ Surface Conditioning Roll | ||||

|---|---|---|---|---|

| Overall Width (Metric) | 101.6 mm, 304.8 mm | |||

| Product Form | Roll | |||

| Grade | Medium, Super Fine, Coarse, Very Fine | |||

| Low Stretch | No | |||

| Mineral Type | Aluminum Oxide, Silicon Carbide |

Scotch-Brite™ Production Clean and Finish Roll

Scotch-Brite™ Production Clean and Finish Roll Scotch-Brite™ High Strength Roll

Scotch-Brite™ High Strength Roll Scotch-Brite™ Clean and Finish Roll

Scotch-Brite™ Clean and Finish Roll